*This is incredibly dangerous - the scabby tools and cobbled together parts shown here are widow makers. Treat them as such.*

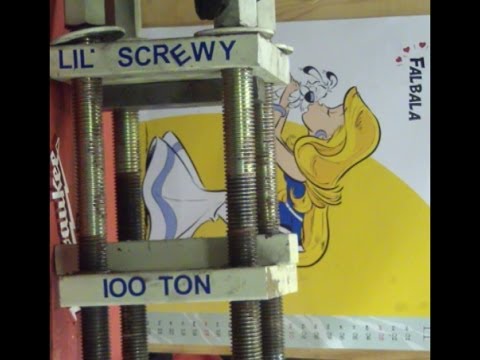

I'll show you how I machined a portable die press for punching and broaching. We're using the latest in Armstrong technology to build a hydraulic press, without hydraulics! 100 tons for 100 dollars in material.

Also of interest in the vid:

17mm die punch thru 8mm steel plate (20 ton trial run)

Annular cutters on the Bridgeport Mill

how to get the last drop of never seize out of the can

neodymium magnets

Milwaukee 8 inch Death Metal Cutting Saw

New Milwaukee 18V drill

Unobtainium sintered pixie dust drill bits

(SFPCD compliance statement: no drill bits were harmed in the making of this video.)

4:16 worst google CC transcription ever.

I'll show you how I machined a portable die press for punching and broaching. We're using the latest in Armstrong technology to build a hydraulic press, without hydraulics! 100 tons for 100 dollars in material.

Also of interest in the vid:

17mm die punch thru 8mm steel plate (20 ton trial run)

Annular cutters on the Bridgeport Mill

how to get the last drop of never seize out of the can

neodymium magnets

Milwaukee 8 inch Death Metal Cutting Saw

New Milwaukee 18V drill

Unobtainium sintered pixie dust drill bits

(SFPCD compliance statement: no drill bits were harmed in the making of this video.)

4:16 worst google CC transcription ever.

It's an excellent video, thank you. Why did you make a center 2' hole on the bottom plate?

Boop

How did you figure out that the pressure is 100 tons?

After watching many of your videos, I really enjoyed the older/younger video/ you. It’s very refreshing.

I just done made me one myself. But mine has six screws. But hand tapping six holes isn’t fun.

Whaaaat is that paint color? I love it!

I cant stop laughing at the attempts of the subtitles to translate what you are saying!

are there any plans for presses like these with mechanical information, and calculations for stuff like the size of the bolts? i am interested in being able to deep draw unibody gas bottles, and that requires like 200 tons of pressure. where can i find more information about this?

Edit : There are drawing calculators online. Best bet is to just make less diameter reductions with the dies

i feel like it would be best to have those bolts and nuts machined custom. make them out of O1 tool steel, harden them, and bring the temper to, like, a blue. maybe even try and through-temper it somehow. ive tried to make my own steel drill bits this way, and anything less than plum color temper just snaps. same for the nuts, with really thick threads. you can potentially make some really tough material that way. you'd have to drill everything with high speed steel or carbide though lol. can a 12L14 base plate handle this sort of pressure?

lol the subtitles are great

Nothing better in the hole world than a new drill bit!

You're pronouncing the magnets wrong, bro.

It's " neodiddlyum "

"We're about a blonde one off…" 😂